Joliet Iron and Steel Works

Columbia St, Joliet, IL 60432

Abandoned ruins of the iron and steel works mill

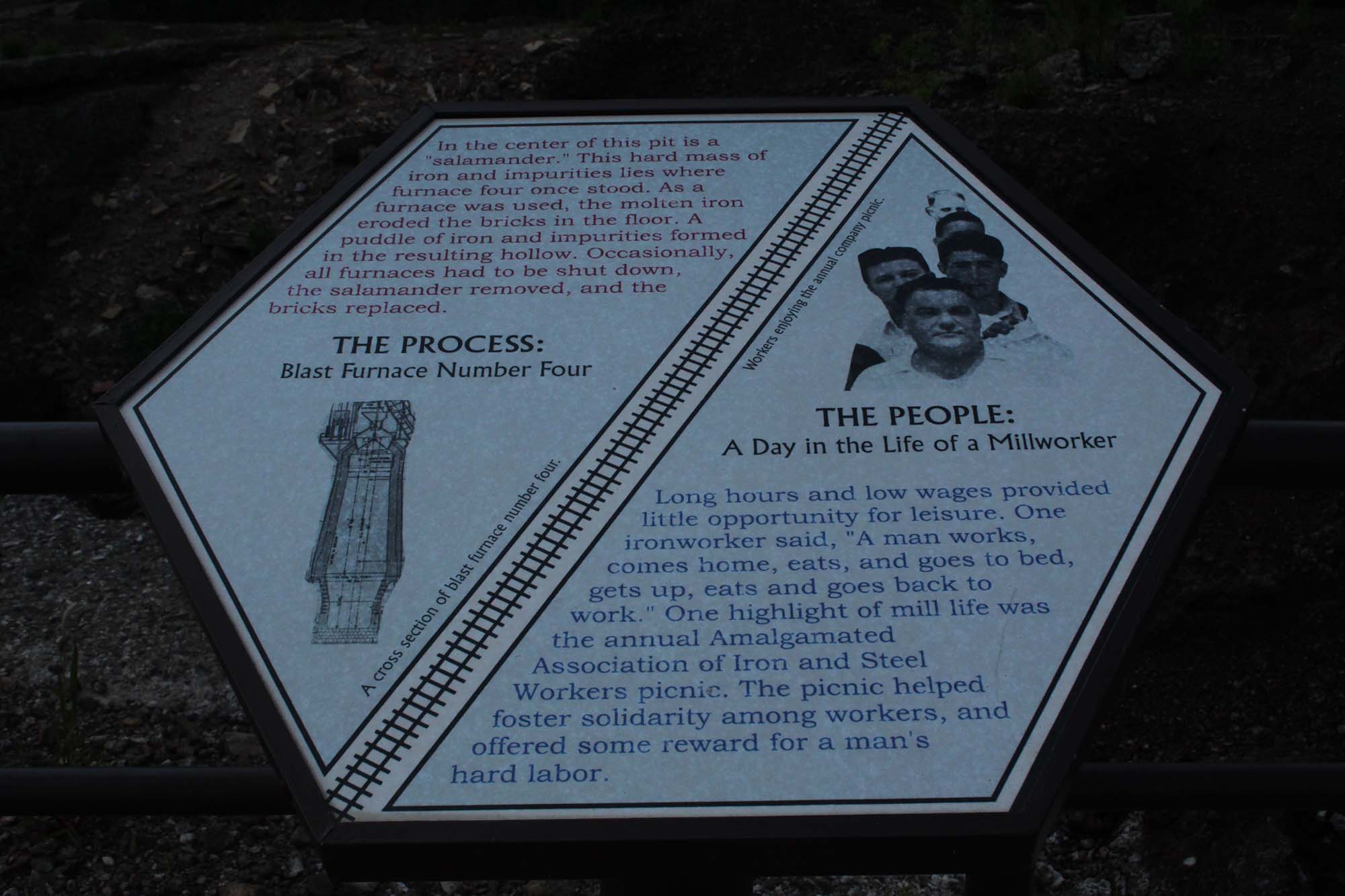

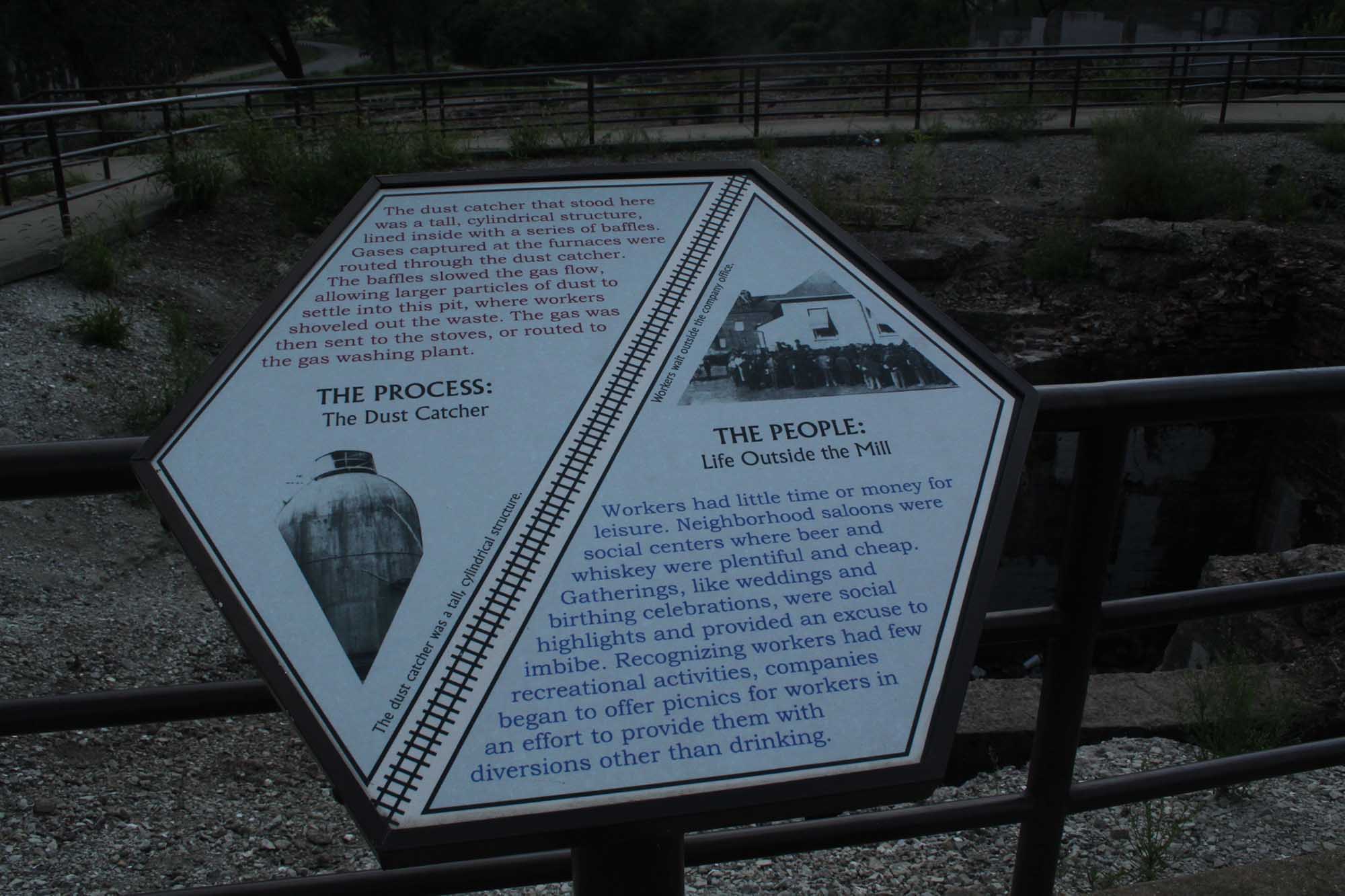

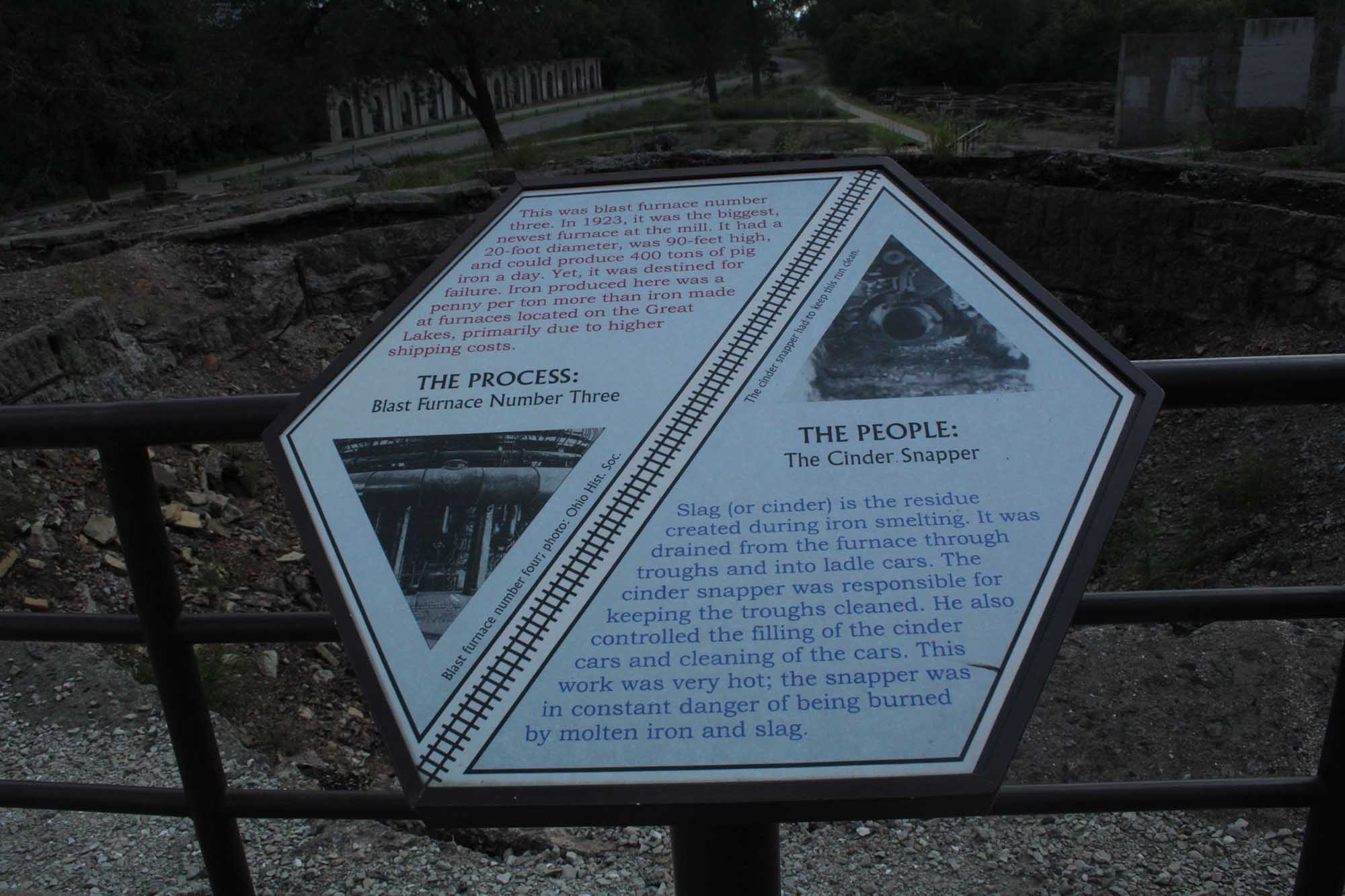

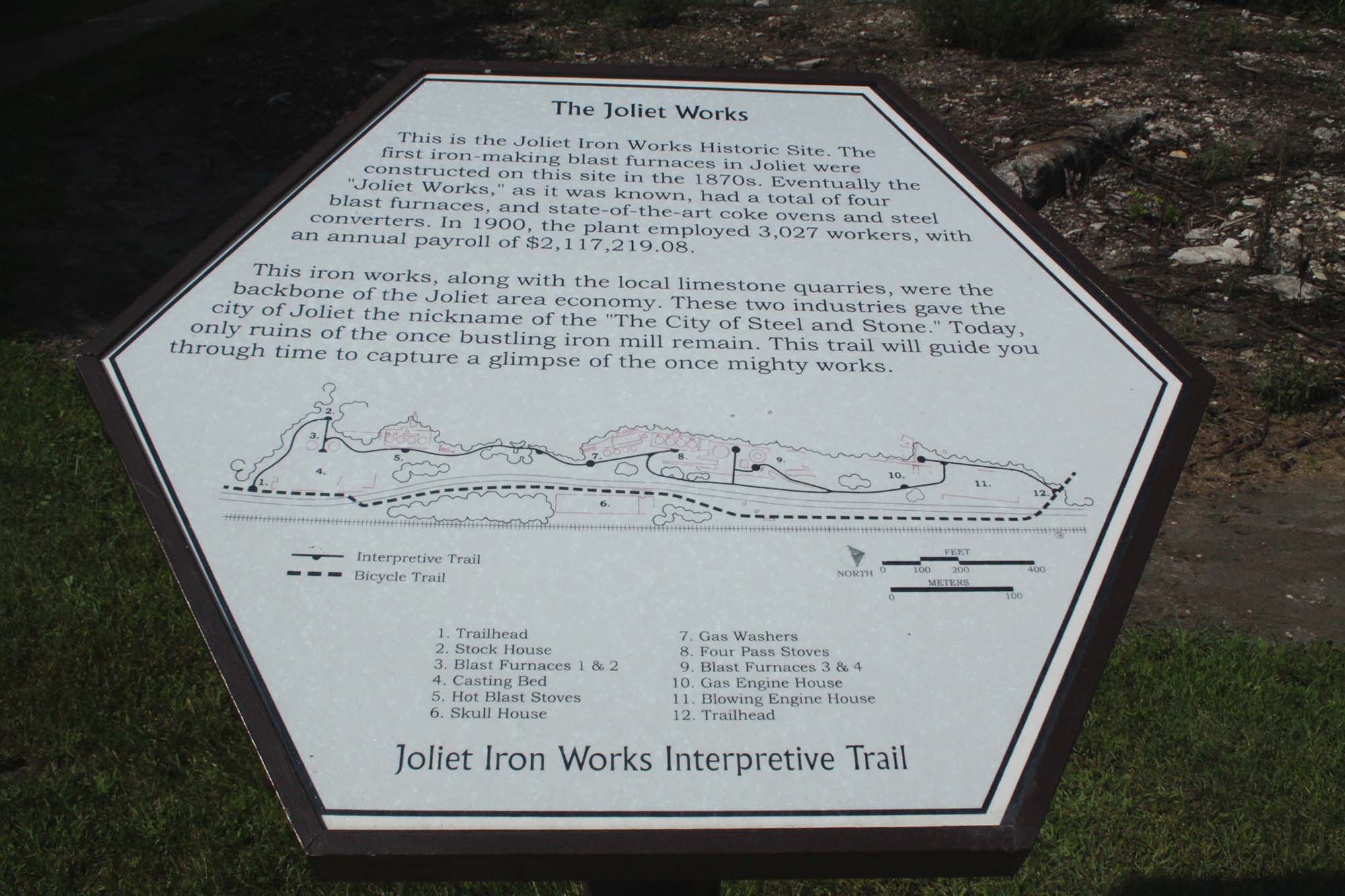

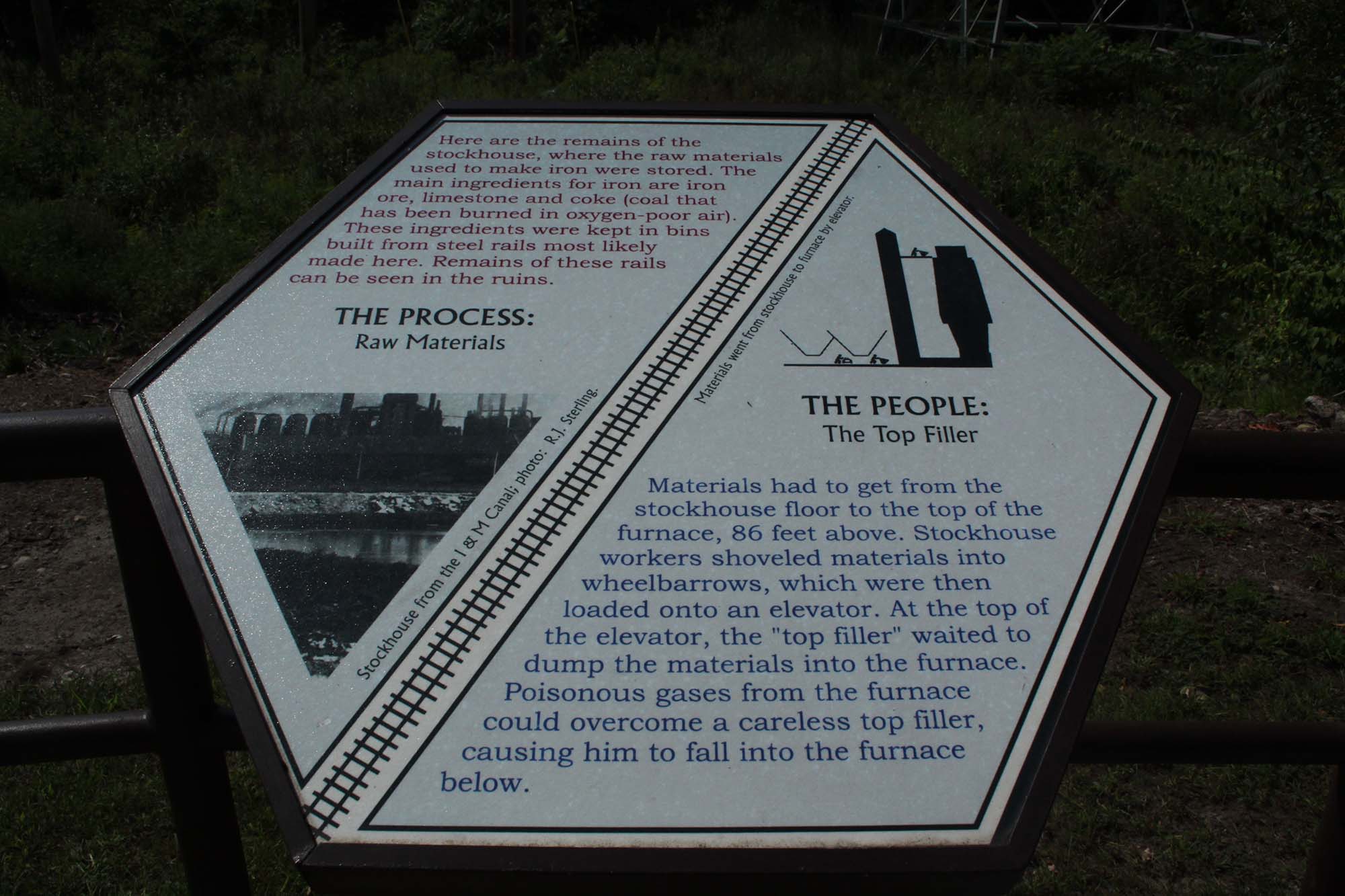

The Joliet Iron and Steel Works Mill was an abandoned steel mill that has been preserved as a historic site by the Forest Preserve District of Will County, Illinois. Today, a 1.5 mile paved pedestrian trail provides a view of the ruins. There are interpretive signs that explain the steel and iron making process and the skills and lives of the workers.

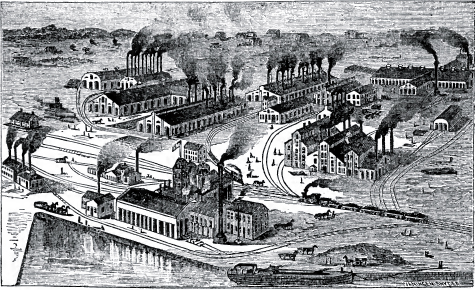

The steel and Iron mill operated from 1869 through 1936. Due to lack of profit the mill was completely shut down by the 1980s. The original mill was operated by the Joliet Iron and Steel Company. It was acquired by Illinois Steel. It later was bought by Federal Steel and then it became US Steel.

Most of the early production by the steel mill was railroad rails. The Joliet mill contributed greatly to America’s railroad infrastructure.

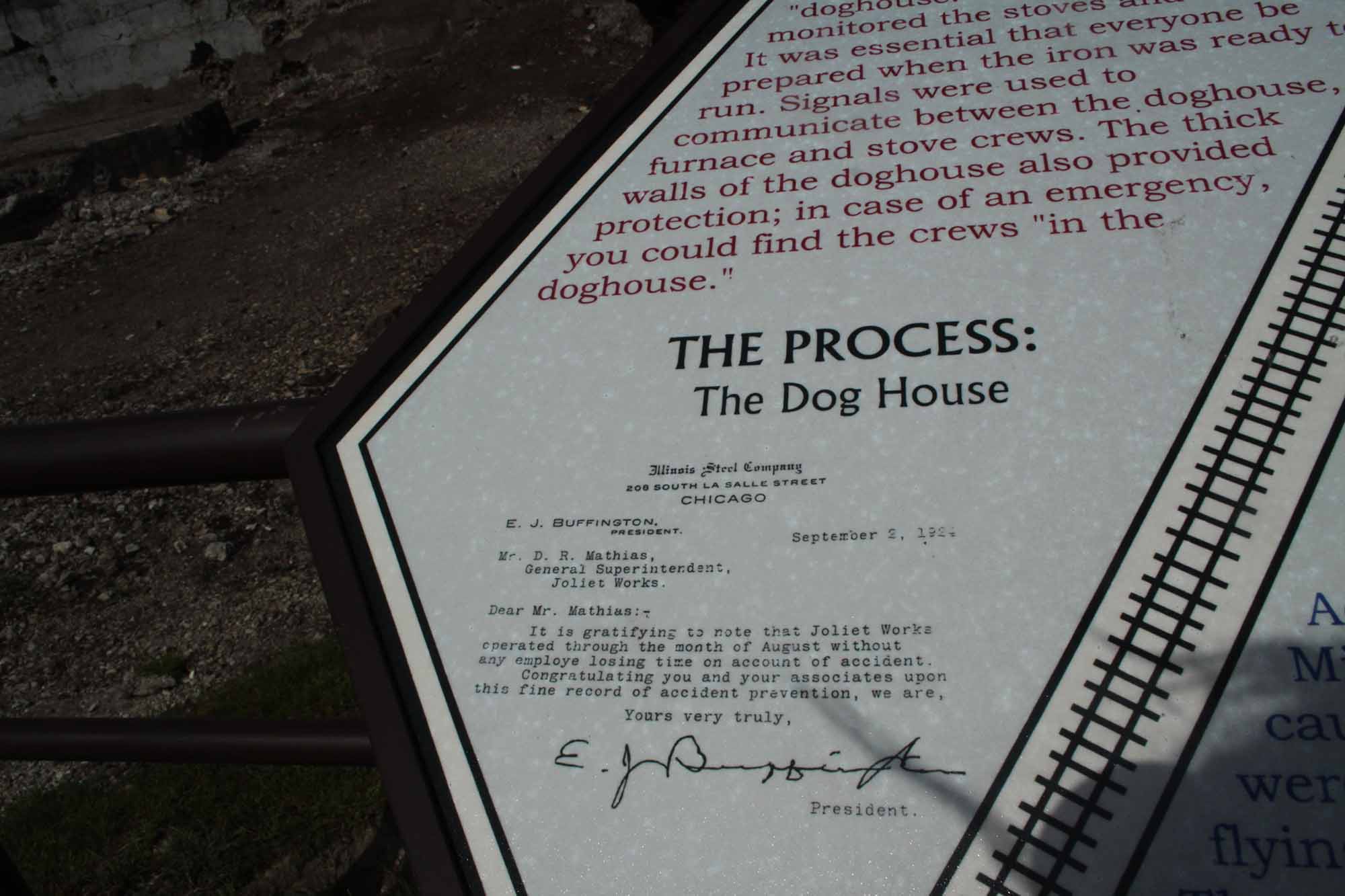

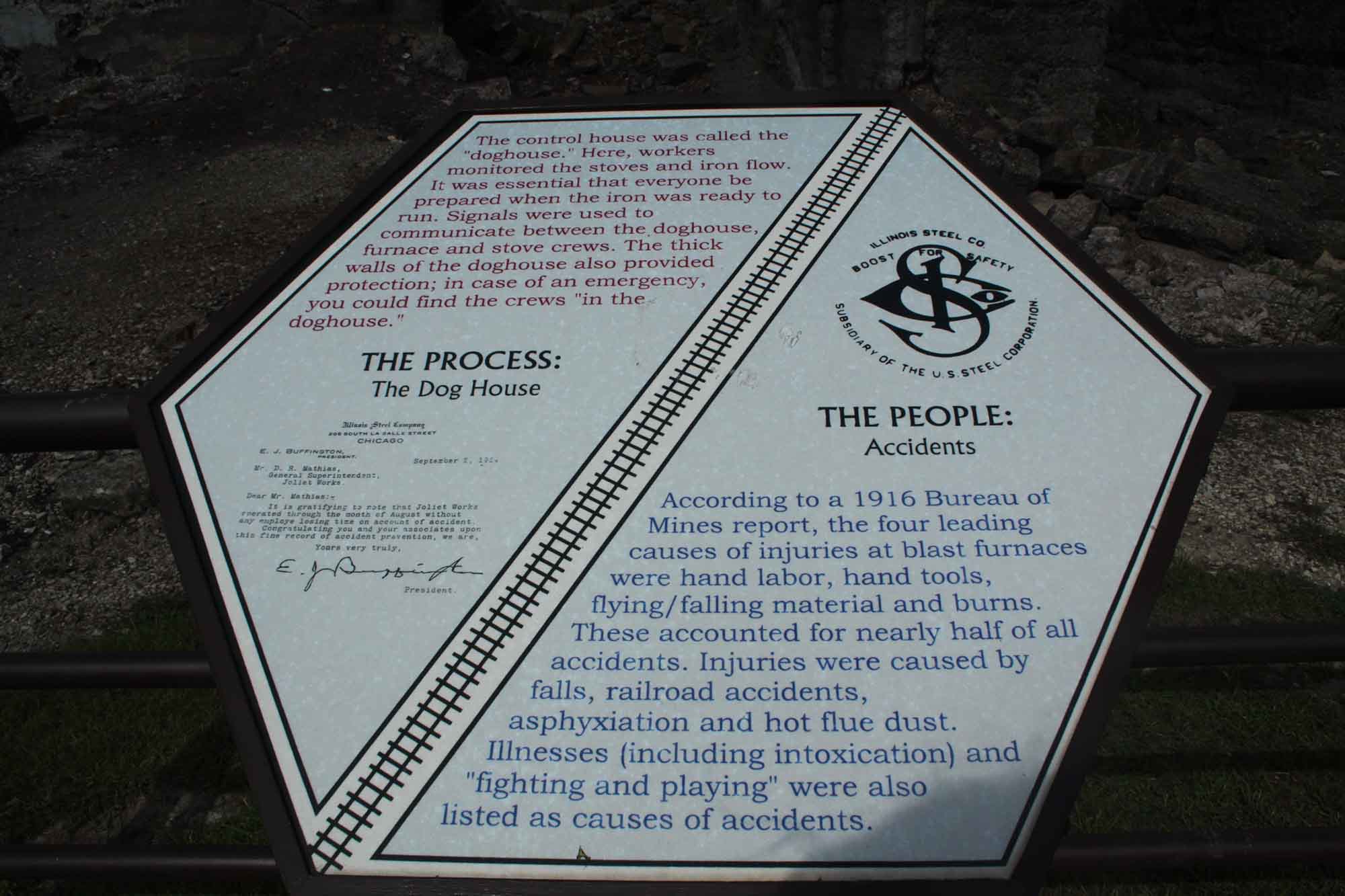

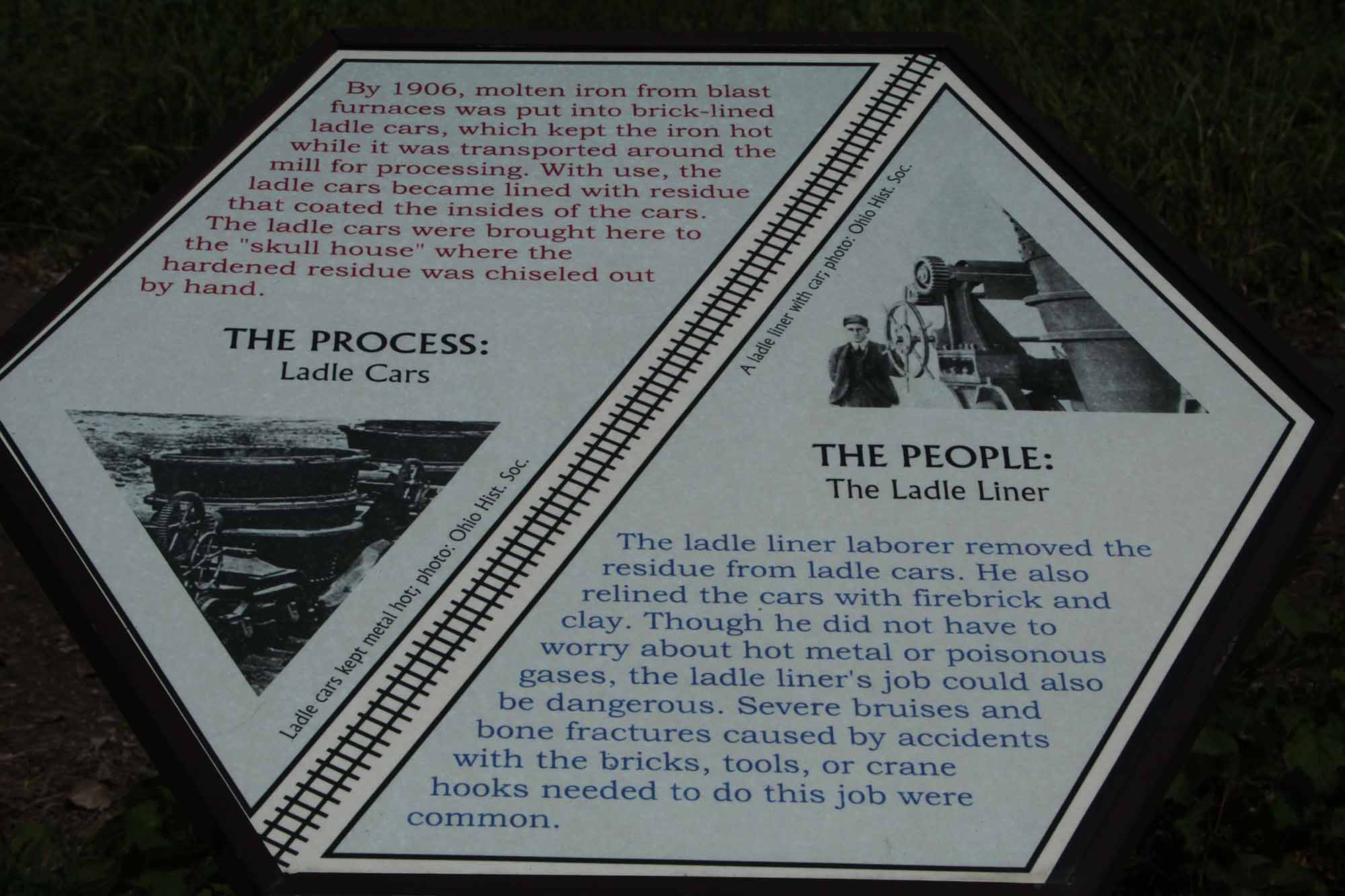

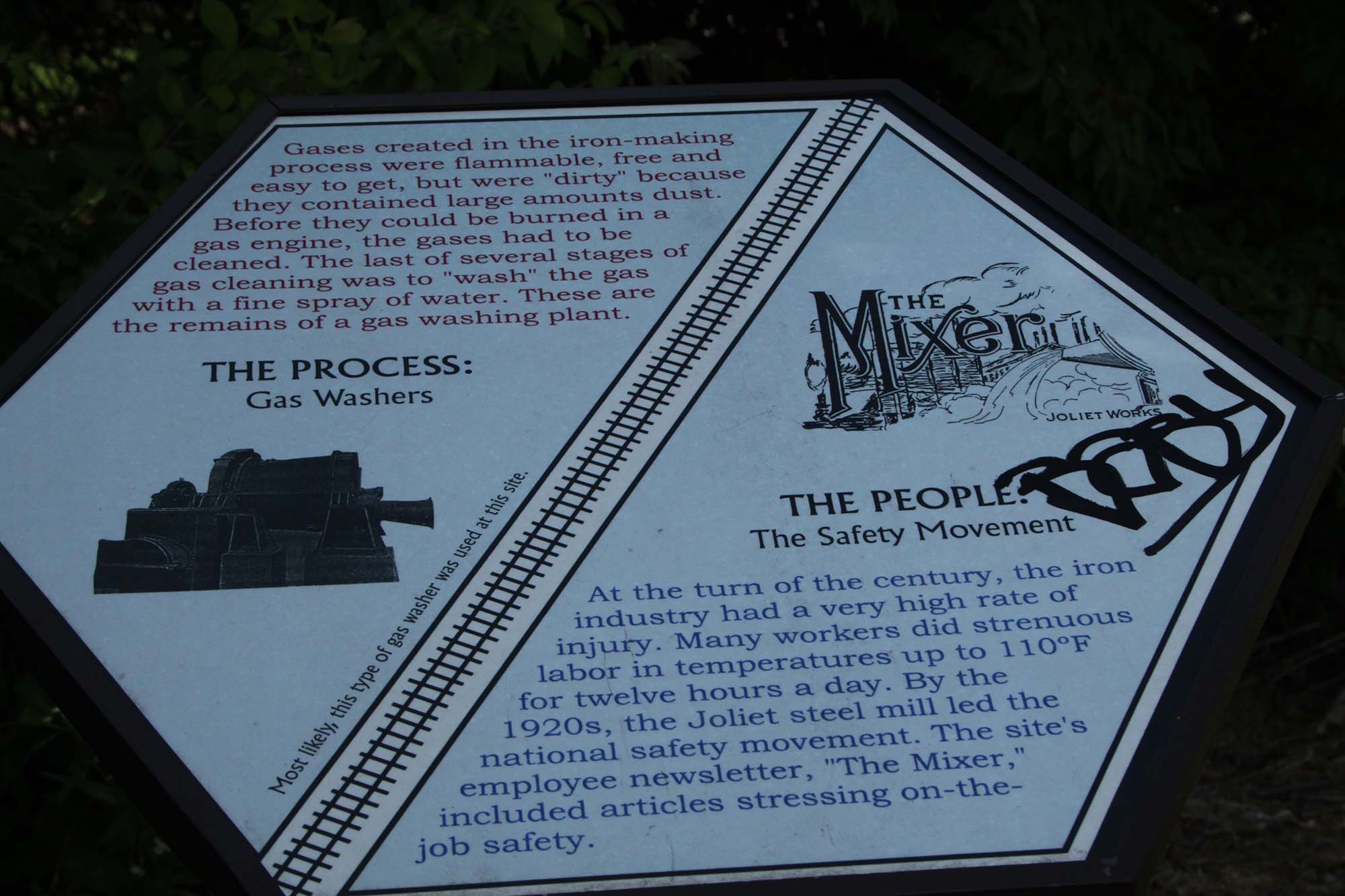

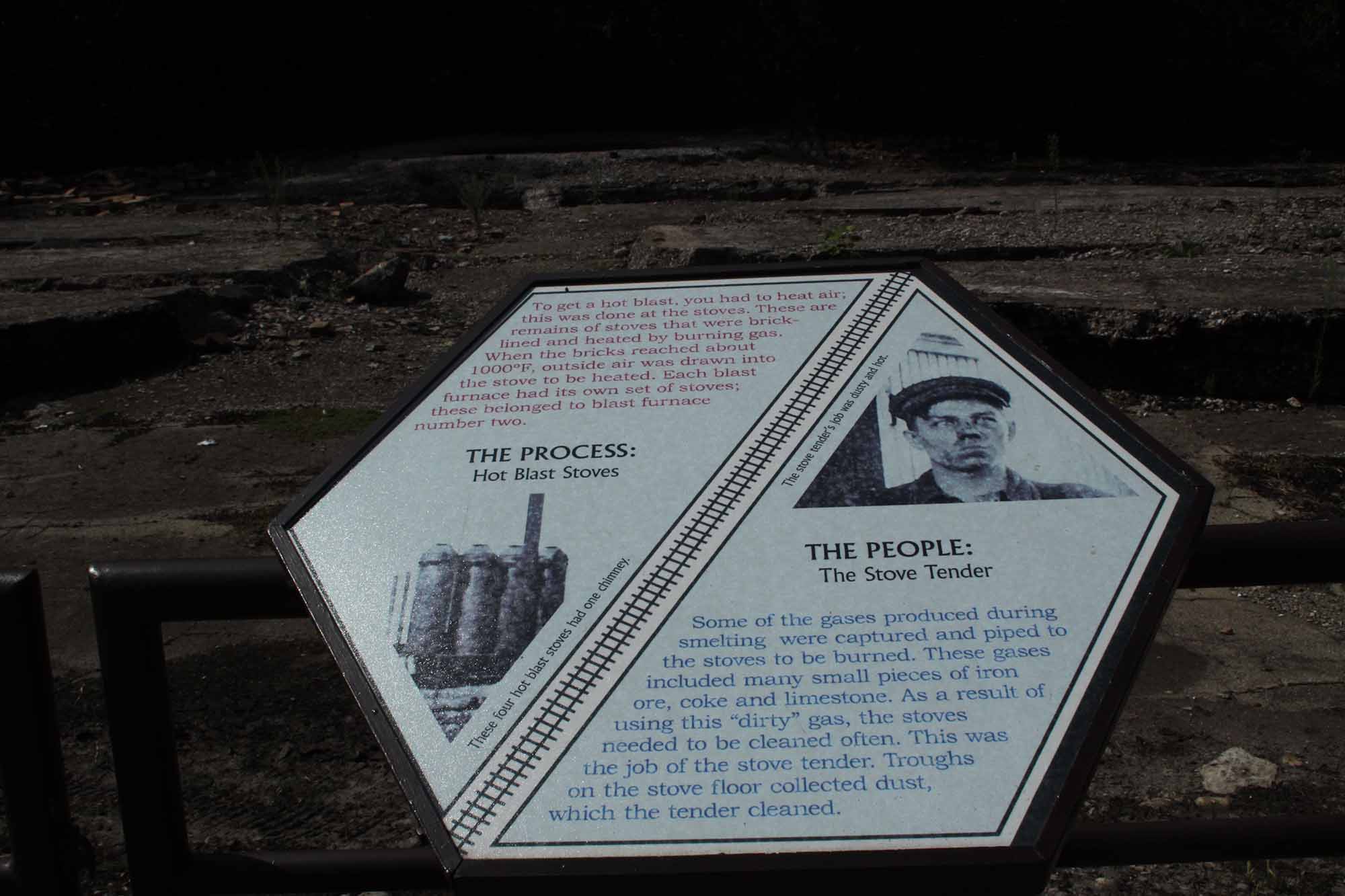

The plant had its own power source by utilizing a dam on the Des Plaines River. The mill’s facilities had numerous buildings, including a stock house, a casting house, hot blast stoves, a skull house, a gas washing plant, a blowing engine house, pass stoves, the dog house and a gas engine house.

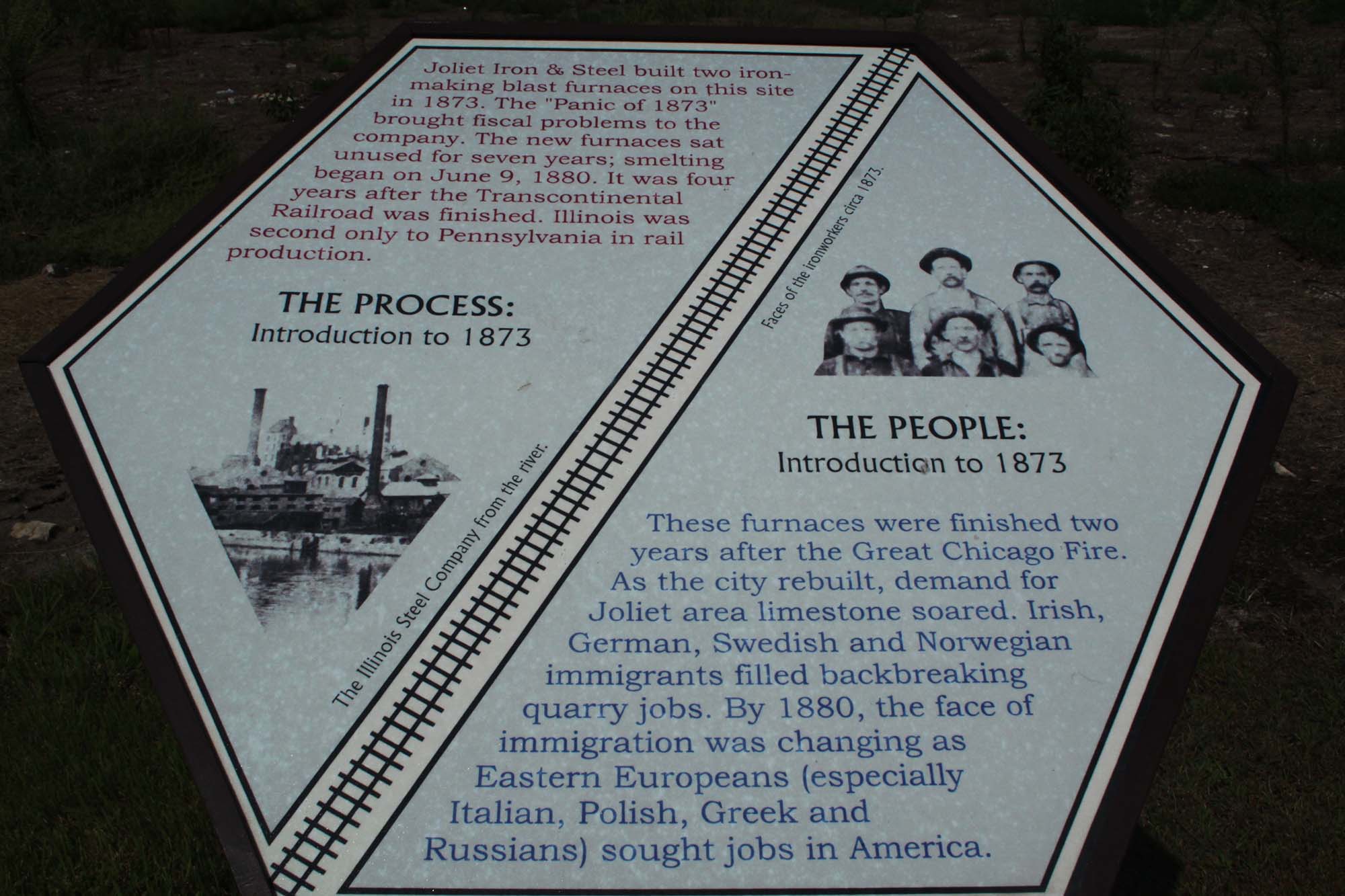

In 1873, Joliet Iron and Steel built the first two blast furnaces. Due to fiscal troubles, the furnaces sat unused for seven years. In June of 1880, the smelting began. Illinois was second only to Pennsylvania in rail production. Immigrants filled hard labor positions of quarrying after the great Chicago fire during the time of rebuilding. The first wave of immigrant laborers were Irish, German, Swedish and Norwegian. As the plant began production a second wave of immigrants sought labor from Eastern Europe including, Italy, Russia, Poland and Greece.

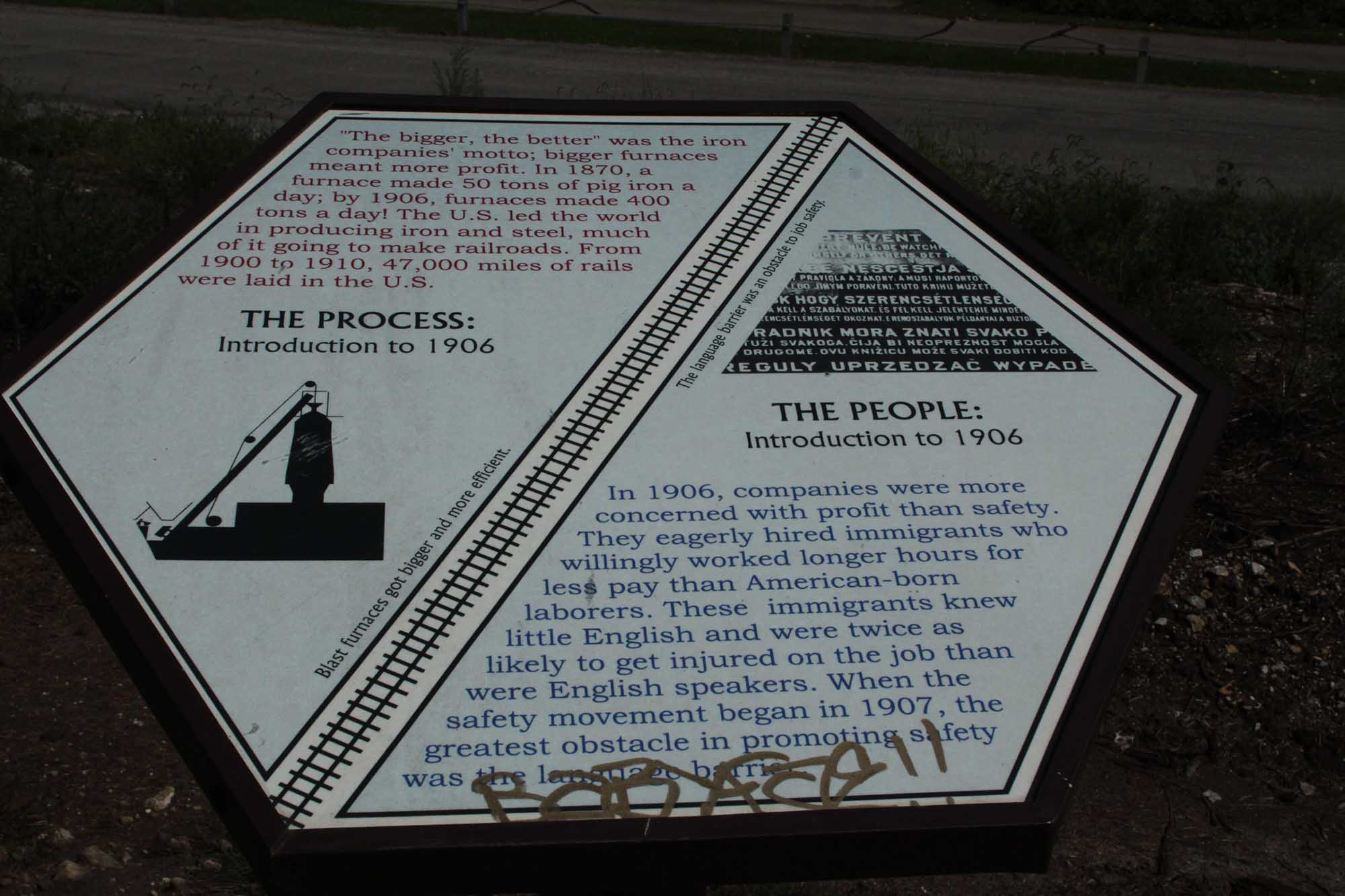

The Bigger the Better was the steel industry motto: meaning more profit. In 1870, a furnace made 50 tons of pig iron a day. By 1906 the furnaces were making 400 tons a day. The workers increased production at the steel mill, but this also came at a price for the laborers. Many of the immigrant workers received less pay, did not speak English, and were highly susceptible to injury and death.

By the 1920’s the Joliet Mill was the national leader in worker safety. This was important since the workers had to work in extreme conditions including, twelve hour days, temperatures of 110 degrees, strenuous manual labor and toxic materials. In 1916 the Bureau of Mines reported the four leading causes of injuries at blast furnaces were hand labor, hand tools, flying/falling materials and burns. These were caused by falls, railroad accidents, asphyxiation and hot flu dust. Fighting and playing was also listed as a cause of accidents.

At the height of the iron and steel industry the U.S. led the world in production. Much of the production went to the thousands of miles of rail road tracks. Steel production and the Joliet Steel Works made a large contribution to America’s industrial age.

All photos by abandonedexplorers.com ©

Source information: Joliet Iron Works Historic site trail information

Amazon Links

Abandonedexplorers.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

As an Amazon Associate I earn from qualifying purchases.

Etsy -The Experiment Lab

Check out my Etsy shop for cool handcrafted items.